|

Ethylbenzene Production Diagnostic |

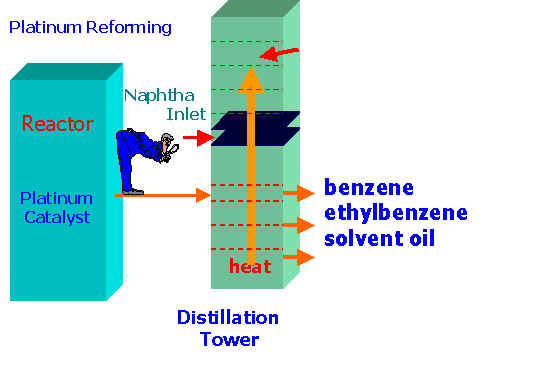

Figure - 1 The production setup of ethylbenzene by platinum reforming in a chemical plant.

Background:

In chemical manufacturing, distillation tower is used where a platinum reforming process takes places. Naphta is fed through an inlet to the tower where heat and platinum catalyst are applied to naphta to produce ethylbenzene and many other chemical products, as shown in the figure.

Problem:

ethylbenzene yield was low after platinum reforming.

the

Objective:

ethylbenzene yield.

Isolate and fix the problem (fault) in the distillation tower and the manufacturing process, so as to fix it and increase theApproach:

operations data from the history of the tower was analyzed and data mining was used to build a mathematical model for the yield as a function of several variables including those related to the tower layout. The model was used to adjust the position of the naphtha inlet.

Finding:

Result:

The position of the Naphta inlet was not optimized.

After moving the inlet up from layer 99 to layer 111, the ethylbenzene production was increased by 35%.