|

Steel Making Equipment Diagnostics |

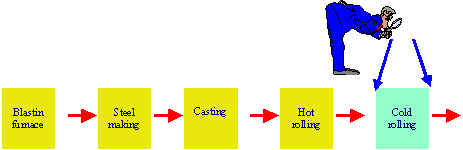

Figure-1 A 5-stage process in steel making.

Background: An iron and steel company uses an advanced steel rolling equipment made in Germany to produce 10,000 tons of ST14 steel plate per year. The plate is used for automobile body. The manufacturing process is divided in 5 stages: blasting furnace, steel making, casting, hot rolling and cold rolling. The problem: the deep pressing property of the ST14 plates is off spec.

Problem: the "deep pressing" property of the ST14 steel plate is off-spec.

Objective: diagnose the equipment setup and isolate the problem(s) that degrades the product property.

Method used: operation records of the rollers were used to build a mathematical model which was then adopted to analyze the target (steel quality) in connection with the factors that affect the target.

Factors: there are about 20 factors in each of the 5 production stages, and the total number of factors are 100 = 5x20. However, MasterMiner™ found out that the following 2 major factors have most influence on the product quality:

- N2 - Nitrogen content of steel should be reduced

- D1/D2 - ratio of the diameter of the 2 cold rollers at the 5th stage.

- Finding: adjust D1/D2, the ratio of the two roller diameters, to improve the ST14 property.

Result: the fraction of off-spec steel plates in production was reduced by 5 times .